PET bottle aseptic cold filling production line with its unique process, widely used in acid drinks, neutral non-protein drinks and neutral protein drinks production.This production line is matched with online inspecting equipment, which can greatly reduce labor cost, improve production efficiency, and help food and beverage manufacturers realize intellectualization of their factories.

The online inspecting equipment used in PET bottle aseptic cold filling production line mainly includes: bottle preform mouth inspector, capping liquid level coding three-in-one inspector, label inspector and weight inspector.

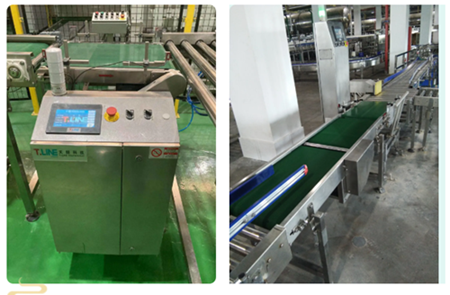

Bottle preform mouth inspector

The equipment takes a 360-degree high-definition video of the preform through a high-speed industrial camera, analyzes and processes the data to judge whether the product is qualified or not.The system can detect the crack, damage, debris, the dirt and impurities on the side of the mouth, and the sprue cutting, etc.

Capping liquid level coding three-in-one inspector

This machine is composed of detection unit, man-machine interface, control unit, rejecting mechanism and other main parts. It is suitable for high-speed PET bottling production line of capping liquid level coding detection. The equipment can detect no cap, high cap, crooked cover, broken bridge, ring defect, miscellaneous cap, liquid level detection, high liquid level, low liquid level,ink jet code and so on.

Label inspector

This machine is composed of detection unit, man-machine interface, control unit, rejecting mechanism and other main parts, suitable for high-speed PET bottling production line label detection.The equipment can carry out no label detection, fold label detection, crack label detection, cohesion label detection, dislocation label detection, high and low label detection.

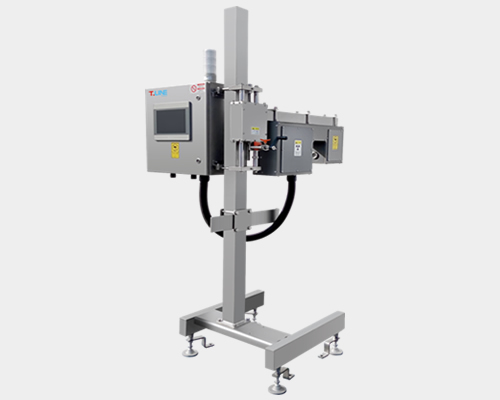

Weight inspector

The equipment is suitable for automatic weight detection, underweight detecting, missing packing detecting and missing accessories detecting of online production of whole case products. It is widely used in beverage, food, pharmaceutical, daily chemical, electronics, industrial products, hardware, military and other industries with harsh net content of products.

T.LINE technology co., ltd is specializing in online detecting equipment research and development and manufacturing for soft drinks, beer, food, pharmaceutical industries. "Realize factory intelligence" is the direction of T.LINE efforts, equipment running 20,000 hours without failure is the quality commitment of T.LINE products. Every T.LINE people with sincere heart, whether for products or customers, are doing their best.

QQ客服

QQ客服